Multiphase reactors are widely used in the chemical industry, energy, metallurgy, and other industrial applications. To overcome limitations related to the design, optimization, and scale-up of multiphase reactors, it is very important to accurately simulate the complex multiphase flows, which involve multiscale multiphase hydrodynamics, simultaneous heat/mass transfer, and chemical reactions.

We aim to (1) understand the multi-scale physical and chemical phenomena such as multiphase flow, heat and mass transfer, chemical reaction, external fields (light, magnetism, etc.) in the multiphase chemical reactors, and their coupling mechanism, (2) construct multi-scale mathematical models or machine-learning (ML) assisted models to simulate the complex multiphase chemical reactor and develop accurate and efficient multiphase computational fluid dynamics (CFD) solver to simulate large-scale industrial reactors.

Advanced Experiment

Multiscale Modeling

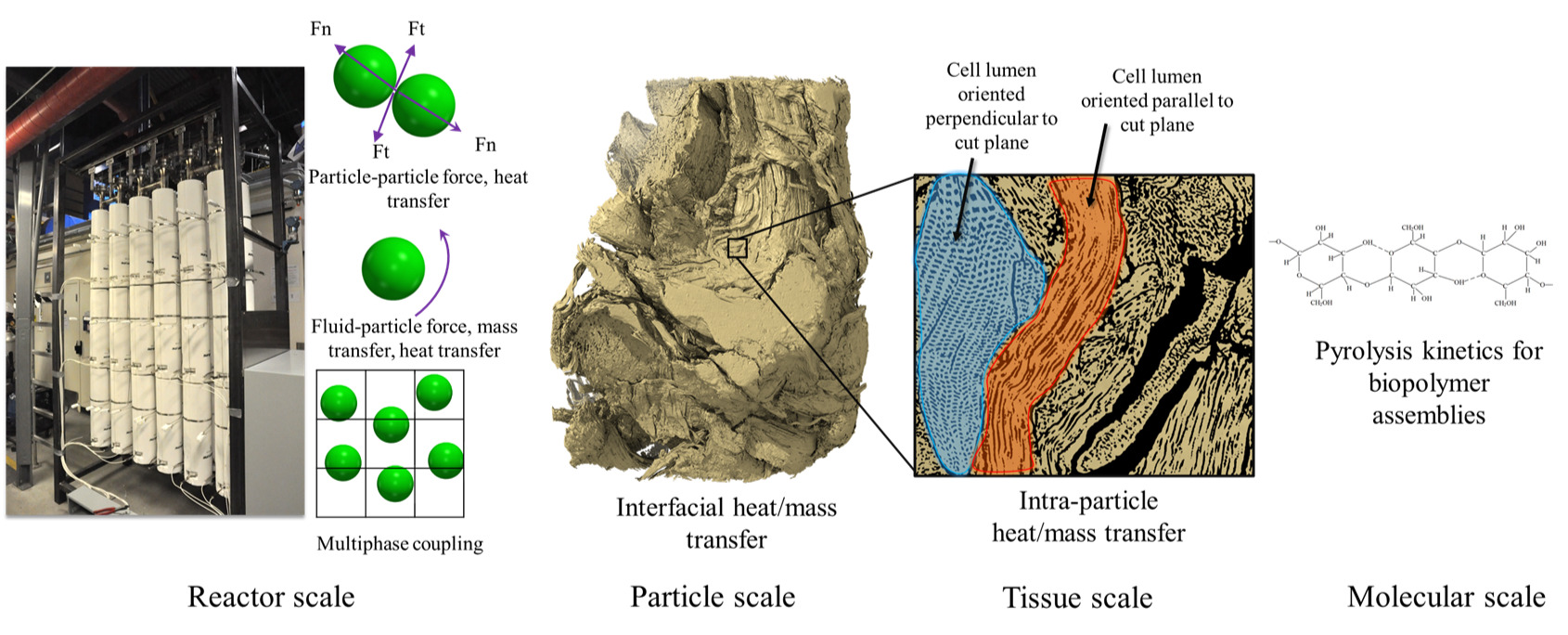

Understanding the complex, multi-scale phenomena in chemical reactors is imperative to achieving effective reactor designs and process scaleup. Multiphase reactor modeling approaches using computational fluid dynamics (CFD) simulations offers a robust, scalable method for investigating biomass catalytic mechanisms. In multiphase chemical reactors, the chemical and physical processes at different scales are highly coupled, which makes it very challenging to accurately and efficiently model the couping processes. Separate models for different scales are extensively studied and exist for a long time. For example, reduced-order models and 3D particle-resolved models are available to simulate the intraparticle heat and mass transport, species diffusion, and chemical reaction at the particle scale. Two fluid model (TFM), discrete element model (DEM), and multiphase particle in cell (MPPIC) model have been developed to simulate the multiphase flow hydrodynamics, heat and mass transfer, and chemical reaction at the reactor scale. However, a multiscale simulation approach to bridge the particle and reactor scales is lacking in the literature.

We developed a multiscale simulation framework for a pyrolizer by integrating a detailed pyrolysis kinetic mechanism, a particle-scale model, and a reactor scale model.